How can you check slack adjusters cdl – Ensuring the proper functionality of slack adjusters is crucial for CDL holders to maintain the safety of commercial vehicles. This comprehensive guide delves into the regulations, inspection procedures, and troubleshooting techniques for slack adjusters, empowering CDL holders with the knowledge to keep their vehicles in optimal condition.

Checking Slack Adjusters with a CDL

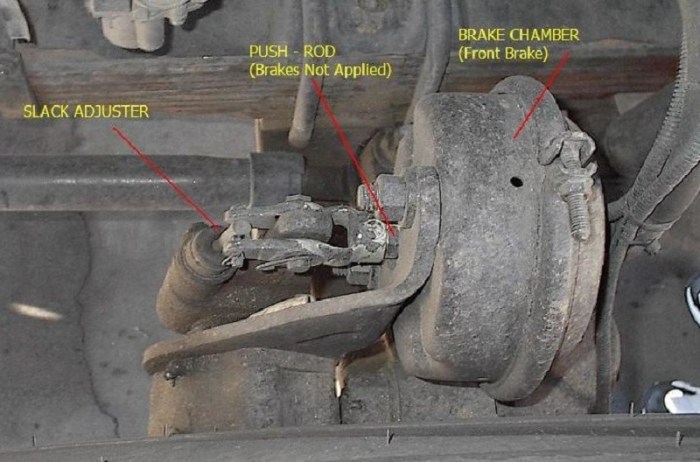

Slack adjusters are crucial components of commercial vehicles’ braking systems, ensuring optimal performance and safety. CDL (Commercial Driver’s License) holders are responsible for maintaining and inspecting these adjusters regularly to comply with regulations and ensure vehicle safety.

Federal Motor Carrier Safety Administration (FMCSA) regulations mandate that CDL holders must check slack adjusters during pre-trip inspections and as part of periodic maintenance. Proper slack adjustment prevents excessive brake lining wear, brake fade, and premature component failure, minimizing safety risks.

Manual Inspection

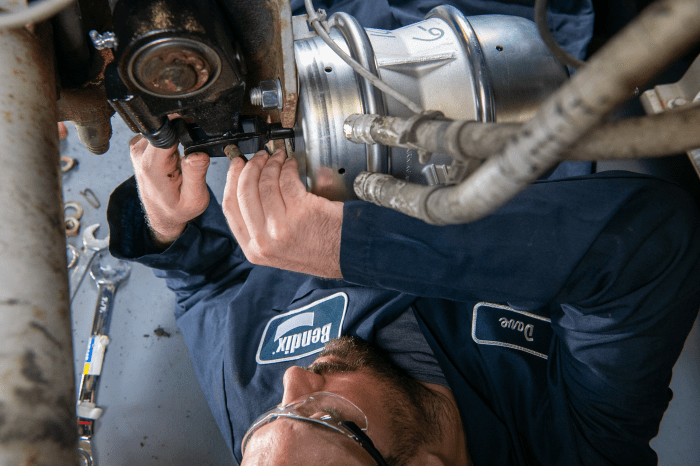

To manually inspect slack adjusters, follow these steps:

- Engage the parking brake and chock the wheels.

- Locate the slack adjusters on the brake chambers.

- Using a wrench, turn the adjusting nut until the brake shoes or pads just make contact with the brake drum or rotor.

- Back off the adjusting nut 1/4 to 1/2 turn.

- Repeat for all slack adjusters on the vehicle.

Using Specialized Tools

Specialized tools, such as a brake lining thickness gauge or a slack adjuster tool, can also be used for more precise and efficient slack adjuster inspection.

Brake lining thickness gauges measure the remaining lining thickness, indicating when replacement is necessary. Slack adjuster tools simplify the adjustment process, providing accurate and consistent results.

Types of Slack Adjusters and Their Inspection Methods

Slack adjusters are critical components in commercial vehicle braking systems, ensuring optimal brake performance and safety. They automatically adjust the brake slack to compensate for brake lining wear, maintaining proper brake engagement and preventing excessive brake drag. There are several types of slack adjusters used in commercial vehicles, each with its specific inspection procedures and advantages and disadvantages.

Automatic Slack Adjusters

Automatic slack adjusters are the most common type used in commercial vehicles. They utilize a ratchet mechanism that automatically adjusts the brake slack as the brake linings wear. Inspection Procedure:

- Check the automatic slack adjuster for any visible damage or leaks.

- Verify that the adjuster is properly mounted and secure.

- Ensure the ratchet mechanism is functioning correctly by manually actuating the adjuster.

- Inspect the brake linings for wear and ensure they are within the specified wear limits.

Advantages:

- Automatic adjustment eliminates the need for manual adjustment, reducing maintenance time and improving safety.

- They maintain consistent brake performance throughout the life of the brake linings.

Disadvantages:

- Automatic slack adjusters can be more expensive than manual adjusters.

- They may require more frequent inspections and maintenance to ensure proper functioning.

Manual Slack Adjusters

Manual slack adjusters require periodic manual adjustment to maintain proper brake slack. They are typically used in older commercial vehicles or as a backup to automatic slack adjusters. Inspection Procedure:

- Check the manual slack adjuster for any visible damage or leaks.

- Verify that the adjuster is properly mounted and secure.

- Manually adjust the slack adjuster according to the manufacturer’s specifications.

- Inspect the brake linings for wear and ensure they are within the specified wear limits.

Advantages:

- Manual slack adjusters are less expensive than automatic slack adjusters.

- They provide greater control over the brake adjustment process.

Disadvantages:

- Manual adjustment requires regular maintenance, which can be time-consuming and inconvenient.

- Incorrect adjustment can lead to poor brake performance or premature brake wear.

Camshaft Slack Adjusters

Camshaft slack adjusters use a camshaft to adjust the brake slack. They are typically found in heavy-duty commercial vehicles and trailers. Inspection Procedure:

- Check the camshaft slack adjuster for any visible damage or leaks.

- Verify that the camshaft is properly mounted and secure.

- Ensure the camshaft is rotating freely and not binding.

- Inspect the brake linings for wear and ensure they are within the specified wear limits.

Advantages:

- Camshaft slack adjusters provide precise and reliable brake adjustment.

- They are less prone to wear and tear than other types of slack adjusters.

Disadvantages:

- Camshaft slack adjusters can be more expensive than other types of slack adjusters.

- They may require specialized tools and expertise for proper inspection and maintenance.

Troubleshooting Slack Adjuster Issues

Maintaining optimal slack adjuster performance is crucial for safe and efficient braking. Troubleshooting common issues ensures timely resolution and prevents costly repairs or accidents.

Slack adjusters can encounter various problems, primarily caused by improper installation, lack of lubrication, wear and tear, or contamination. Identifying and resolving these issues requires a systematic approach.

Diagnosis and Troubleshooting

- Loose or Improperly Adjusted Slack Adjuster:This can lead to excessive brake lining wear, reduced braking efficiency, and potential brake failure. Tighten or adjust the slack adjuster as per manufacturer specifications.

- Frozen or Seized Slack Adjuster:Caused by corrosion, dirt, or lack of lubrication. Inspect for any obstructions or damage. Clean, lubricate, and free up the mechanism or replace the slack adjuster if necessary.

- Broken or Worn Components:Over time, components like springs, levers, or pawls can break or wear out. Inspect for any visible damage or excessive play. Replace damaged components to restore proper operation.

- Contamination:Dirt, grease, or other contaminants can interfere with the slack adjuster’s operation. Clean and inspect the components, ensuring they are free from debris.

Importance of Regular Maintenance and Inspections

Regular maintenance and inspections are essential for preventing slack adjuster failures and ensuring optimal braking performance. Inspecting the slack adjusters visually and manually during routine maintenance checks can identify potential issues early on.

Regular lubrication of moving components and cleaning of any debris or contaminants helps extend the lifespan of slack adjusters and prevent premature wear or damage.

By addressing slack adjuster issues promptly and implementing a proactive maintenance schedule, fleets and drivers can enhance safety, reduce downtime, and maintain efficient braking systems.

Consequences of Improper Slack Adjuster Maintenance

Neglecting slack adjuster maintenance can lead to severe consequences, jeopardizing vehicle performance, safety, and compliance.Improperly adjusted slack adjusters can impair braking effectiveness, increasing stopping distances and compromising the driver’s ability to control the vehicle. This can result in accidents, particularly in emergency situations.

Impact on Vehicle Performance

- Reduced braking efficiency

- Increased stopping distances

- Premature brake wear

Impact on Safety

- Increased risk of accidents

- Reduced driver control

- Impaired emergency braking

Impact on Compliance

- Failure to meet regulatory standards

- Potential legal liabilities

- Insurance coverage issues

Examples of Accidents

- A truck with faulty slack adjusters failed to stop at an intersection, colliding with another vehicle, resulting in multiple injuries.

- A bus with improperly adjusted slack adjusters experienced a brake failure while descending a hill, leading to a catastrophic crash.

Best Practices for Slack Adjuster Inspection and Maintenance: How Can You Check Slack Adjusters Cdl

Regular inspection and maintenance are crucial for ensuring optimal performance and extending the lifespan of slack adjusters. This involves establishing recommended inspection intervals and maintenance schedules, implementing preventive maintenance programs, and following best practices to keep slack adjusters in good working order.

Recommended Inspection Intervals and Maintenance Schedules, How can you check slack adjusters cdl

The frequency of slack adjuster inspections and maintenance depends on various factors, including the type of vehicle, operating conditions, and manufacturer’s recommendations. However, a general guideline is to conduct inspections every 6-12 months or as per the manufacturer’s specified intervals.

Maintenance schedules should include regular lubrication, cleaning, and adjustment of slack adjusters. Lubrication helps reduce friction and wear, while cleaning removes dirt and debris that can interfere with proper operation. Adjustment ensures that the slack adjuster maintains the correct amount of slack in the brake system, preventing excessive wear and premature failure.

Preventive Maintenance Programs

Implementing a preventive maintenance program can significantly enhance slack adjuster performance and longevity. Such programs involve proactive inspections and maintenance tasks performed at predetermined intervals, regardless of the condition of the slack adjusters.

Preventive maintenance programs help identify potential issues early on, preventing them from escalating into major problems. They also ensure that slack adjusters are consistently maintained to optimal standards, reducing the likelihood of breakdowns and costly repairs.

Tips for Keeping Slack Adjusters in Good Working Order

In addition to regular inspections and maintenance, several best practices can help keep slack adjusters in good working order and extend their lifespan:

- Use high-quality slack adjusters from reputable manufacturers.

- Install slack adjusters correctly and according to the manufacturer’s instructions.

- Avoid overtightening or undertightening slack adjusters.

- Protect slack adjusters from dirt, moisture, and corrosion.

- Inspect slack adjusters regularly for signs of wear, damage, or leaks.

Popular Questions

What are the regulations for CDL holders regarding slack adjusters?

CDL holders are required to inspect slack adjusters regularly and ensure they are properly adjusted and functioning correctly.

What are the different types of slack adjusters?

There are various types of slack adjusters, including manual, automatic, and air-operated, each with specific inspection procedures.

What are the common problems associated with slack adjusters?

Common problems include improper adjustment, worn components, and contamination, which can affect braking performance.